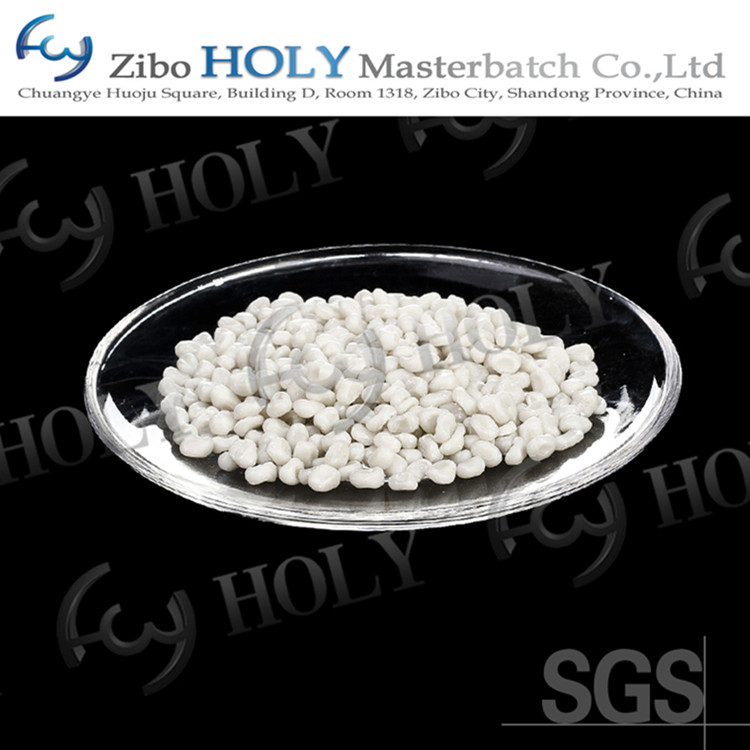

Masterbatch for Plastic Injection Molding Parts

Basic Info

Model No.: H-01

Product Description

Model NO.: H-01 Usage: General Plastics, Engineering Plastics, Specialty Plastics, Blow Film Plastic Forming Method: Extrusion Filler: Talc Carrier Resin: PE Adding Ratio: 5-50% Mfi: 2-6 Trademark: HOLY Specification: content 80%-85% Material: Powder and Plastic Plastic Properties After Heated: Thermoplastic Plastics Color: White Filler Mesh: 1500 Density (g/cm3): 1.6-1.7 Filler Content: 80% HS Code: 3824909990, 3824909990 Transport Package: 25kg/Bags Origin: China masterbatch for plastic injection molding parts

Product advantages:

1.The oil absorption of the powder value is low, with good fluidity and dispersion, so its the good surface finish of the products.

2. Light Specific grativity, high transparent and brightness, the refractive index close to the PP,PE

3. The high adding ratio is more than 50%.

4. Good dispersion, donnot separate out.

5. Good heat sealing properties, high tensile strength

6. Improve the impact resistance, thermal conductivity and abrasive resistance of the product. Reduce the heat shrinkable property, improve the strength and toughness of the product.

7. Improve the strength and geometric stability of the product, avoid or reduce the shrinkage of injection molding

Product Data:

Product applications: a. Blow Film ( shopping bags, casting film, multilayer film, etc.)

b. Blow Molding ( Medical & Cosmetic container, Lubricant & Paint container, etc)

c. Extrusion Molding ( Sheet, Pipe, Wire & Cable, etc.)

d.Injection Molding ( Automotive, Electronic, Construction, House wares, Furniture, Toys, etc.)

e. Fiber ( Carpet, Textiles, Upholstery, etc.

Exhibition:

Packaging and Delivery:

1. Net weight: 25kg/bags.

2. Compound woven bags.

3. Customerized packaging.

4. Sutible for see transpportation

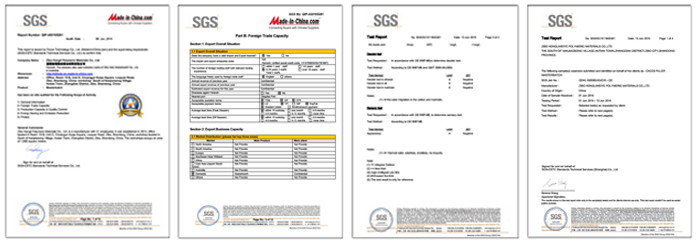

Company Qulification:

Welcome to contact:

Contact us if you need more details on Filler Masterbatch. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Masterbatch Plastic Injection Use、Filler Masterbatch for PE/PP Application. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product advantages:

1.The oil absorption of the powder value is low, with good fluidity and dispersion, so its the good surface finish of the products.

2. Light Specific grativity, high transparent and brightness, the refractive index close to the PP,PE

3. The high adding ratio is more than 50%.

4. Good dispersion, donnot separate out.

5. Good heat sealing properties, high tensile strength

6. Improve the impact resistance, thermal conductivity and abrasive resistance of the product. Reduce the heat shrinkable property, improve the strength and toughness of the product.

7. Improve the strength and geometric stability of the product, avoid or reduce the shrinkage of injection molding

Product Data:

| Name | Talc Filler Masterbatch |

| Surface Color | White |

| Filler | Talc |

| Filler Mesh No. | 1500 |

| Filler Content | ≤85% |

| Carrier Resin | PE |

| MFI (g/10min) | 2-6 |

| Density (g/cm3) | 1.6-1.7 |

| Melt Temperature | 160 |

| Mositure | <=0.01 |

| Adding ratio | 5-50% |

| Application | Film blowing, Injection molding, Blister etc. |

| Packing | 25KG compound woven bags, or customized |

| Storage | Keep the products in a dry, ventilated place, Note to avoid moisture, insolation, rain and breakage in transportation. |

b. Blow Molding ( Medical & Cosmetic container, Lubricant & Paint container, etc)

c. Extrusion Molding ( Sheet, Pipe, Wire & Cable, etc.)

d.Injection Molding ( Automotive, Electronic, Construction, House wares, Furniture, Toys, etc.)

e. Fiber ( Carpet, Textiles, Upholstery, etc.

Exhibition:

Packaging and Delivery:

1. Net weight: 25kg/bags.

2. Compound woven bags.

3. Customerized packaging.

4. Sutible for see transpportation

Company Qulification:

Welcome to contact:

Contact us if you need more details on Filler Masterbatch. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Masterbatch Plastic Injection Use、Filler Masterbatch for PE/PP Application. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Filler Masterbatch > Talc Filler Materbatch

Other Products

Hot Products

Masterbatch for Plastic Packing TubeMasterbatch for Plastic Bottle TopTransparent Barium Filler Masterbatch for Film BlowingCaCO3 Filler MasterbatchMoulding Black Masterbatch 2016c1Yellow Masterbatch Y3500Green Masterbatch G6209White Masterbatch W9219bSpinning Black Masterbatch 2030cLow Grade MB for Granulation 1611Economical Grade Black Masterbatch for Extrusion 2003fLow Grade Injection Masterbatch 2003fDark Blue Color Masterbatch B5206Brilliant Red Masterbatch (R-2212)Excellent Black Masterbatch with The Cheapest Price for Blowing Film (BK-2003F)High Quality Recycled Black Masterbatch for Film 2030