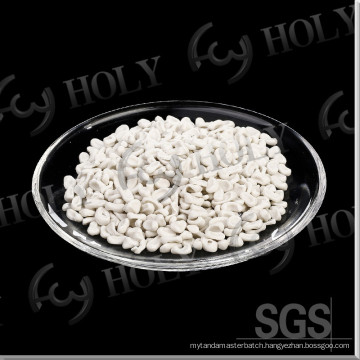

CaCO3 Filler Masterbatch

Basic Info

Model No.: IC

Product Description

Model NO.: IC Usage: General Plastics, Engineering Plastics, Specialty Plastics Plastic Forming Method: Extrusion Filler: Calcium Carbonate Filler Mesh: 800 Mfi (G/10min at 190ºC): 1-15 Moisture: 0.01 Application: Blow Film Transport Package: 25kg/Bags Origin: Shandong, China Material: Powder and Plastic Plastic Properties After Heated: Thermoplastic Plastics Color: White Filler Content: 80% Carrier Resin: PE Density (g/cm3): 1.6-1.7 Adding Ratio: 5-50% Trademark: HOLY Specification: Plastic resin 20% HS Code: 3824909990 Product advantages:

1. Using the nano modified caco3 powder as the filler.

2. Keep the film's physical properties of surface gloss and toughness, so will not affect the printing on the film.

3. Good dispersion, so that the film without crystal spots and not easy to be broken.

4. Good pull, with high adding ratio more than 50%.

5.Non- corrosivity, no damage to the screw and die-head

6. Increase the extrusion output as per unit time, improve the production efficiency and reduce the total production cost.

Product Data:

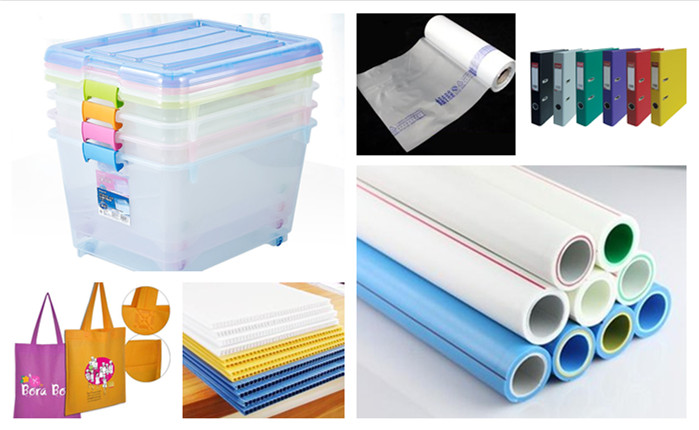

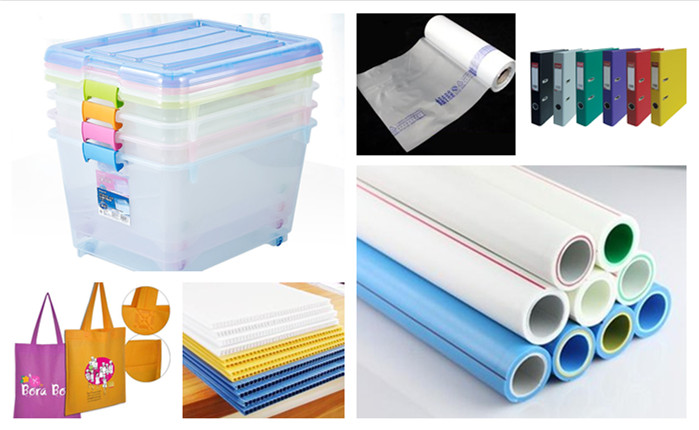

Product applications:

Applied for PE&PP products,sush as:blown film, blown moulding, injection moulding, hollowing, casting, wiredrawing, sheets and so on.

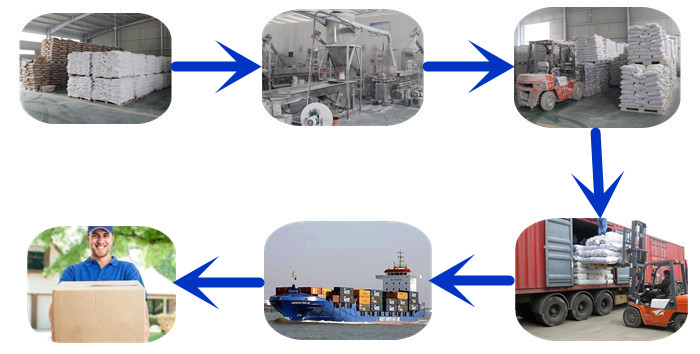

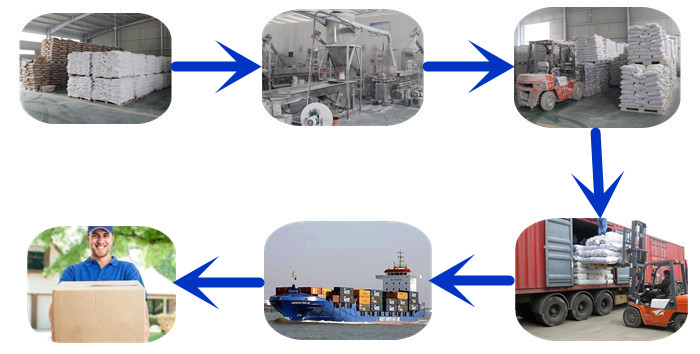

Production & Factory:

Packaging and Delivery:

1. Net weight: 25kg/bags.

2. Compound woven bags.

3. Customerized packaging.

4. Sutible for see transpportation

Welcome to contact:

Contact us if you need more details on Filler Masterbatch. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Filler Masterbatch、CaCO3 Filler Masterbatch. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Filler Masterbatch. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Filler Masterbatch、CaCO3 Filler Masterbatch. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Using the nano modified caco3 powder as the filler.

2. Keep the film's physical properties of surface gloss and toughness, so will not affect the printing on the film.

3. Good dispersion, so that the film without crystal spots and not easy to be broken.

4. Good pull, with high adding ratio more than 50%.

5.Non- corrosivity, no damage to the screw and die-head

6. Increase the extrusion output as per unit time, improve the production efficiency and reduce the total production cost.

Product Data:

| Name | CaCO3 Filler Masterbatch |

| Surface Color | White |

| Filler | Caco3 |

| Filler Mesh No. | 800 |

| Filler Content | ≤85% |

| Carrier Resin | PP/PE |

| MFI (g/10min at 190ºC) | 1-15 |

| Density (g/cm3) | 1.6-1.7 |

| Moisture | <0.01 |

| Adding ratio | 5-50% |

| Application | Film blowing, Injection molding, Blister etc. |

| Packing | 25KG compound woven bags, or customized |

| Storage | Keep the products in a dry, ventilated place, Note to avoid moisture, isolation, rain and breakage in transportation. |

Applied for PE&PP products,sush as:blown film, blown moulding, injection moulding, hollowing, casting, wiredrawing, sheets and so on.

Production & Factory:

Packaging and Delivery:

1. Net weight: 25kg/bags.

2. Compound woven bags.

3. Customerized packaging.

4. Sutible for see transpportation

Welcome to contact:

Contact us if you need more details on Filler Masterbatch. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Filler Masterbatch、CaCO3 Filler Masterbatch. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Filler Masterbatch. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Filler Masterbatch、CaCO3 Filler Masterbatch. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Filler Masterbatch > CaCO3 Filler Masterbatch

Premium Related Products

Other Products

Hot Products

Masterbatch for Plastic Packing TubeMasterbatch for Plastic Bottle TopTransparent Barium Filler Masterbatch for Film BlowingCaCO3 Filler MasterbatchMoulding Black Masterbatch 2016c1Yellow Masterbatch Y3500Green Masterbatch G6209White Masterbatch W9219bSpinning Black Masterbatch 2030cLow Grade MB for Granulation 1611Economical Grade Black Masterbatch for Extrusion 2003fLow Grade Injection Masterbatch 2003fDark Blue Color Masterbatch B5206Brilliant Red Masterbatch (R-2212)Excellent Black Masterbatch with The Cheapest Price for Blowing Film (BK-2003F)High Quality Recycled Black Masterbatch for Film 2030